Further Information

If you would like further information, we would be very pleased to contact you for a detailed consultation. Or you can contact us at

Linde AMT Schluechtern GmbH

Breitenbacher Straße 40

36381 Schlüchtern

Germany

Phone: +49(0) 6661 9678-0

Fax: +49(0) 6661 9678-90

lg.de.info.schluechtern@linde.com

HYDROCER™ ceramic dampening roller

High Quality Offset Printing with the HYDROCER™ ceramic dampening roller

- Economical concentration of fountain concentrate for adjusting the value and for wetting the white areas

- Reliable removal of comb and cord stripes

- Fountain solution is transferred at a high rate if required by printing material and print form

- Extremely thin water films if required by printing material, print forms and inks

- Rapid balancing of ink and water, especially for critical inks

- Expansion of the dampening margin

- Reduction of costs for concentrates

- Printing materials almost free of fountain solution residues, especially important for food and pharmaceutical packaging

Mode of operation

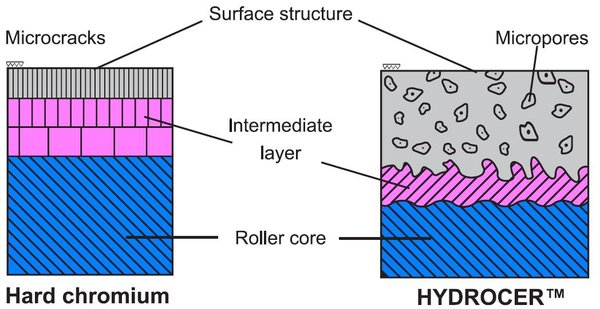

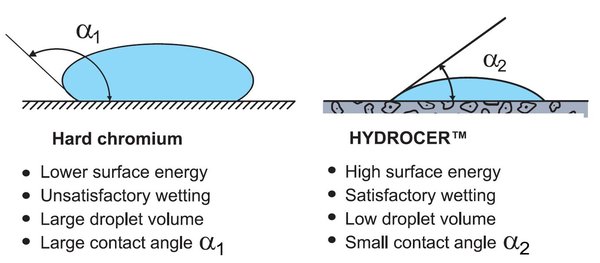

Micropores on the surface of the HYDROCER™ dampening roller greatly improve the water transportation characteristics – an important advantage over chrome-plated dampening rollers. The displaced volume of the fountain solution is increased by approx. 30%