Further Information

If you would like further information, we would be very pleased to contact you for a detailed consultation. Or you can contact us at

Linde AMT Schluechtern GmbH

Breitenbacher Straße 40

36381 Schlüchtern

Germany

Phone: +49(0) 6661 9678-0

Fax: +49(0) 6661 9678-90

lg.de.info.schluechtern@linde.com

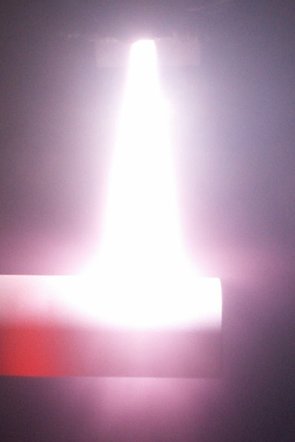

LPPS – Low Pressure Plasma Spraying

Low pressure plasma spraying provides a significant increase in the bond strength, density and purity of the coatings compared to atmospheric plasma spraying.

A low pressure plasma coater basically consists of the following components:

Plasma gun and control unit (plasma gases, powder feed gas, powder supply, current, voltage, cooling water, etc.), power supply (DC), HF-plasma ignition, powder feeders, vacuum tank with motion system for workpiece and plasma gun, filter system, pumping station.