Further Information

If you would like further information, we would be very pleased to contact you for a detailed consultation. Or you can contact us at

Linde AMT Schluechtern GmbH

Breitenbacher Straße 40

36381 Schlüchtern

Germany

Phone: +49(0) 6661 9678-0

Fax: +49(0) 6661 9678-90

lg.de.info.schluechtern@linde.com

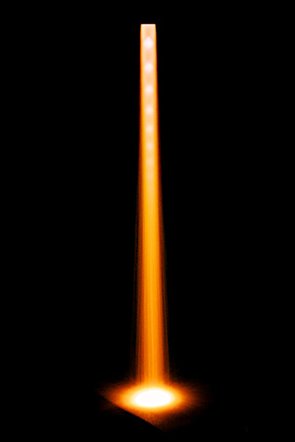

HVOF High Velocity Oxygen Fuel

Since its implementation in the 1980s, High Velocity Oxygen Fuel (HVOF) has gained in importance. Compared to flame spraying and plasma spraying, the powder is accelerated significantly faster and heated up less due to the short dwell time in the flame. A distinction is made between HVOF gas and HVOF liquid fuel fired burners.

The HVOF gas burner can operate with different combustible gases such as propane, acetylene, ethene and various mixed gases.

When using HVOF burners, combustion chamber pressures of 10 bar and more are developed during the combustion of liquid fuel in combination with oxygen, which generates a flame velocity of more than 2000 m/s. This leads to approx. doubling of the kinetic energy of the system compared to the gas fired system.

In terms of porosity, bond strength and hardness, high quality coatings can be achieved.